how to run a cnc milling machine In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine. Unlike a classic cheap tool box, tool chests (and cabinets) have multiple drawers and usually have wheels so you can (fairly easily) move hundreds of pounds of tools around the garage as needed. But there are plenty of tool chests and cabinets out there, and many of them simply aren’t worth it.

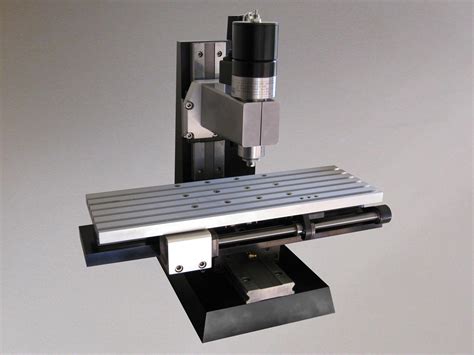

0 · make your own cnc mill

1 · machine to make your own

2 · home built cnc milling machine

3 · do it yourself cnc machine

4 · diy cnc mill kit cost

5 · cnc ready to run projects

6 · build your own milling machine

7 · build your own cnc mill

My building needs a camera pointing at its roof access & the closes power is a 4x4 junction box powering a ceiling LED sconce directly below it. I don’t want to break out of that box & install an outlet I can plug a usb charger into.

In this video, I'll cover all the CNC basics that you must know before being able to run the machine. This includes CAD, CAM, Feeds and Speeds, Toolpaths, G-code, and setting up the machine.Due to its technical nature, learning to run a CNC machine can be overwhelming for beginners. This guide aims to simplify the process by providing clear instructions and practical tips for operating a CNC machine effectively. In this CNC milling machine tutorial, we will provide a comprehensive guide on how to use a CNC milling machine.November 15, 2024. In a nutshell, a CNC milling machine is a cutting-edge piece of equipment that uses programmed instructions to automate the cutting, drilling, and shaping of materials. Unlike manual milling, where an operator’s steady .

make your own cnc mill

machine to make your own

The machinist will then program the directions for the CNC mill to produce the object. CNC machines can mill any material—silicone plastics, wood, stainless steel and nonferrous metals—and are able to produce a wide range . CNC milling machines are used in a variety of industries, from automotive to aerospace, and are prized for their accuracy and efficiency. In this article, we will provide a step-by-step guide on how to set up a CNC milling .Problem is, none of us know how to program or run a cnc milling machine. And at least at first, we wouldnt use it enough to merit hiring a full/part time guy. . end till the other. this is where a machinist/programmer comes into play. i have the knowledge to not only set up and run the machines, but also to program complex surfaces, and .

TITAN Gilroy talks to his guys about how to run the cnc machines faster, which means saving customers money and getting parts out quicker.Subscribe for daily.

A CNC machine hourly rate calculator is an essential tool for estimating the operational costs of computer numerical control equipment. This calculator takes into account various factors such as machine depreciation, . For example, a 3-axis CNC milling machine is typically less expensive to run than a 5-axis CNC milling machine. Additionally, the size of the job and the complexity of the job can also affect the cost of running a CNC machine per hour. For example, a larger job with more complex features may require more time and materials, resulting in a . The following is a step by step guide on how to run a CNC program. We even include a gcode example program to run that will draw a circle. If you don’t have your machine running just yet and would like some guidance, check out How to setup your Arduino CNC Machine. G Code .

rubber edge protector for sheet metal

home built cnc milling machine

russan stone metal footed box lizard

A CNC milling machine is a computer-controlled machine tool used for milling. It is a very versatile machine that can perform many operations. In this . Refers to using various software packages to create toolpaths and NC code to run a CNC controlled machine based on 3D computer model (CAD) data. To run a program on the CNC milling machine, the operator must first load the program into the control software. Once the program is loaded, the operator can select the program and begin running it. During the program’s execution, the operator should monitor the machine’s progress and ensure that it is operating correctly.On some cnc machines the Dry Run is added as a CNC Machine Mode like Fanuc. On Fanuc cnc control you just select the Dry Run mode and cnc machine is now in Dry Run Mode. Introduction of Dry Run for CNC Machines. Setting a new component on a cnc machine is not an easy job. You have to go through many important tasks like cnc machine zero . They set the spindle purge so damn high they think your spindle is upside down in coolant 24/7. Compressed air is one of the most expensive energies in the shop. A small shop with 5 or 8 milling machines with these crazy air purges really add up to a lot of money. Some of my machines have the tamper proof regulators for the spindle purge.

I'm trying to figure out exactly how much can be run from a 200amp(160 amp at 100%duty) single phase service. In reality I'd see myself more likely to have a smaller cnc lathe along the lines of a 5 or 7.5hp gangtool lathe and maybe a robodrill type mill. Would be ideal to run both at the same time, and perhaps even a 3hp manual machine.

How to use Dry Run on cnc machine | CNC Dry Run| Cnc milling Dry Run mode.modes of operation5-axis cnc milling machine basic details || how to run 5th axis || tips for 5-axis operating=====Get the BEST Price at India.The Machine: 3-axis milling machine with a maximum power of 30 HP (22 kW) The Operation: Face milling of stainless steel with a 4″ cutter, at a depth of cut of 0.5″, feed per tooth of 0.005″, and cutting speed of 300 SFM. (100 mm, 12.7 mm, 0.13 mm/tooth, 100 m/min). The power required in this case is about 28 HP (21 KW)

CNC mills are often classified by the number of axes on which they can operate or spindle directions. 1. Vertical Mill. A vertical mill or milling machine’s spindle axis is vertically oriented, which means the cutting tools on the spindle will shape the materials vertically, and the cutters move while the workpiece remains stationary, the machines can cut into the part easily. Watch Next - 3D Printer Basics: https://youtu.be/RgECxaxUIb0CNC Routers for Hobbyists can be intimidating! In this video, I'll cover all the CNC basics that .Load Part: Load part (work piece) in vise or hold your part (work piece) with your machine holding arrangements.; X,Y axis’s Offsetting: Set the part (work piece) offset.For this purpose you may use edge finder or you can do it with your End .

do it yourself cnc machine

5-axis CNC machines can do 3D milling and drilling from various angles, and cost from 0K to 0K. . Generally, you can estimate around /hr for even a more powerful CNC machine in hourly electricity cost. .

One of the most important fundamentals when proofing out a new program, is to dry run all tools above the part. In this tutorial, Stuart will take you throug.

How to Run a Desktop CNC Mill: This instructable is a quick guide to desktop CNC milling with an Othermill, a common small-scale machine that's mainly used for making PCB circuit boards. This machine can do everything a larger machine can, it just has a smaller build platform. . With the stock fixtured and the machine homed, you can run the .

I don't run a drier, I run a water separator right at the compressor, then about 30ft of air hose to the VMC and then another water separator/filter unit on the manifold that I have for supplying air to the CNC. I've never seen any water in the separator on the CNC, only water in the separator attached to the compressor. CNC milling machines can be programmed to create parts with a high degree of accuracy, making them ideal for applications in aerospace, automotive, and medical industries. . Keeping the machine well-oiled and free of debris can help to prevent wear and tear on the components and keep the machine running smoothly. Overall, with the right . Milltronics service and training technician Steve came down to the shop for a few days to help train me using their Milltronics 9000 CNC controllers. The Mil.

CNC machines have revolutionized the manufacturing industry with their precision and efficiency. These automated machines use computer programming to control various operations, including milling and drilling. Understanding how to run a CNC machine is crucial for anyone involved in this field, as it ensures optimal performance and productivity. Part 1 of our "Configuring the Milling Machine" Series. Amelia will explain how to load a program into the CNC Milling Machine. For part 2, go to: https://yo.

Note that using Lulzbot Cura, temperatures are turned on automatically when running from USB tether to computer. However, when running from G-code on SD card, the temperature turn-on is saved in G-Code. Thus, you can only run from G-code if you want to run the Torch Table. Unless you set bed and extruder to 0 temp in the interface?

rust forged metal bracket

This video shows the start-up and home-out procedure for the HASSTM1 CNC Milling Machine Before you run the CNC machine on the actual material, it’s good practice to simulate the machining process using the same CNC programming software. . To program a CNC milling machine effectively, you must also input the material type you are using into the software. Different materials require different milling speeds, feeds, and coolant .

Use the box method to distribute and simplify -2x2+5x4x+2 . Drag and drop t terms to the correct locations of the table. -2x2+5x4x+2 Correct! Now write the simplified answer in .

how to run a cnc milling machine|cnc ready to run projects